Driveshafts/Propshafts

Neapco uses the latest technologies in the design and manufacture of its propshafts/driveshafts to optimize driveline performance and reduce NVH issues for all system configurations. All components and systems are designed and validated in-house to current applicable standards by our staff of experienced driveline engineers. Whether your system configuration is single piece, multi-piece, traditional Cardan, high speed constant velocity joint or other, Neapco has a solution to meet your requirements.

Features and Benefits

Diverse product portfolio — U-joints ranging from 1000 to 1810 series in maintenance-free or greaseable models, with an extensive selection of robust yokes

Center bearings with high vibrational damping characteristics — Designed and balanced to meet high RPM requirements with reduced NVH

Ductile iron or forged steel components — High strength design reduces ear-and-plug deflection for reduced warranty and risk of leaks under load

Robust, durable designs — Long-lasting under constant high power loads in the harshest conditions

Tested and verified — Designs meet performance standards for low maintenance, high speed/high torque and the other requirements of heavy-duty off-highway applications

Custom solutions — Driveline assemblies in a wide range of lengths and torque loads to meet application requirements

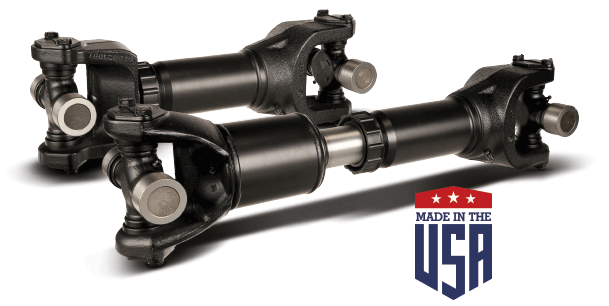

Neapco ShaftSwap® Interaxle Driveshafts

- Ready to install

- Saves time in the driveshaft shop

- Saves time in the service bay

- Gets truck back on the road sooner

- Made in the U.S.A. – Beatrice, NE

eCatalog

For more information on Neapco aftermarket products, please see the eCatalog.