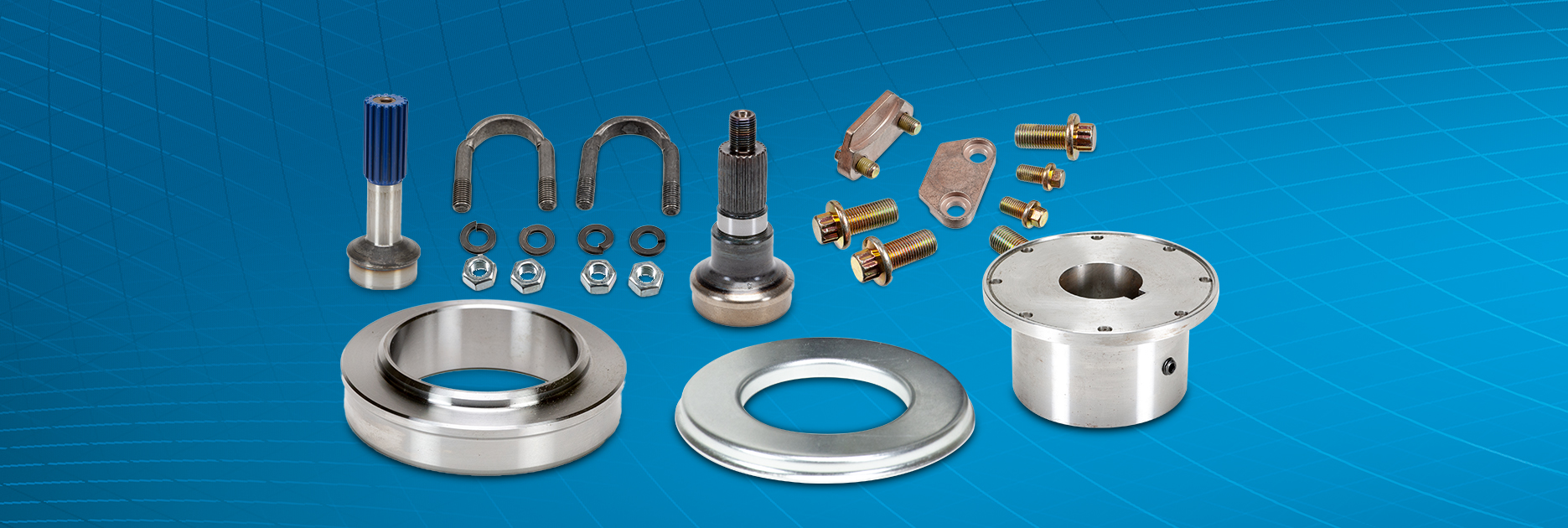

Other Driveline Components

Driveline Components to Solve All Repair, Conversion and Niche Requirements

Neapco all-makes driveline component coverage for light, medium and heavy duty applications is the broadest in the industry, including:

- Exclusive conversion products

- Dealer-only items

- Unique niche products to solve difficult driveline problems

- Repair solutions for non-serviceable drivelines

We offer a full range of components for 1000–1810 series, wing style (2C–15C), AAM 1355–1485 series, and U.S and European agricultural applications (1200-2600 series, and metric series 1-10).

We specialize in developing exclusive conversion products and unique niche products to solve difficult driveline problems. Our component coverage is extensive, and we offer both unwelded assemblies and complete assemblies. We also offer aluminum driveshaft components and tube/yoke kits that allow for repair of this emerging driveline technology.

Tested to OE Quality and Performance Standards

Our driveline component designs are tested and validated as part of our commitment to providing aftermarket parts that meet or exceed OE quality and performance standards. Our driveline components are produced using state-of-the art technology and manufacturing processes that allow for precision machining and control of tight tolerances.

Our light-heavy duty driveline component offering includes a full complement of part types, including but not limited to weld yokes, slip yokes, stub shafts, flange yokes and flange socket yokes, end yokes, centering and H yokes, CV head assemblies, companion flanges and driveline tubing.

Features and Benefits

Slip yokes and stub shafts machined to tight tolerances — Minimizes axial movement and/or hinging. We are considered the industry leader in providing heavy duty slip yokes and stub shafts with superior fits

Dynamically balanced heavy duty slip yokes — Reduces or eliminates imbalance issues when assembling or repairing a driveshaft

Nylon coated stub shafts — Prevents premature wear and axial movement

Ductile iron or forged steel components — High strength design reduces ear-and-plug deflection for reduced warranty and risk of leaks under load

Broad array of aftermarket double-Cardan CV head assemblies — Many with Neapco’s proprietary lubrication system for the linkage between the CV yokes

Pre-straightened tubing — Digitally controlled tight-tolerance straightening reduces the time to repair and balance a driveshaft in your facility, saving you time and money

eCatalog

For more information on Neapco aftermarket products, please see the eCatalog.